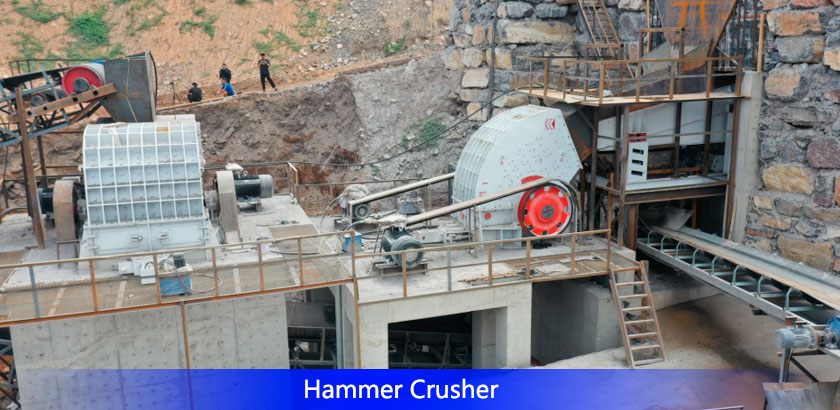

Hammer crusher is a new type of crushing equipment, suitable for crushing various brittle materials of medium hardness, and is widely used in mining, chemical, building materials, metallurgy, cement and other industries. The unique design structure and high production efficiency are welcomed by the majority of mine owners. Below, Xingaonai Heavy Industry will take you to learn more about the hammer crusher.

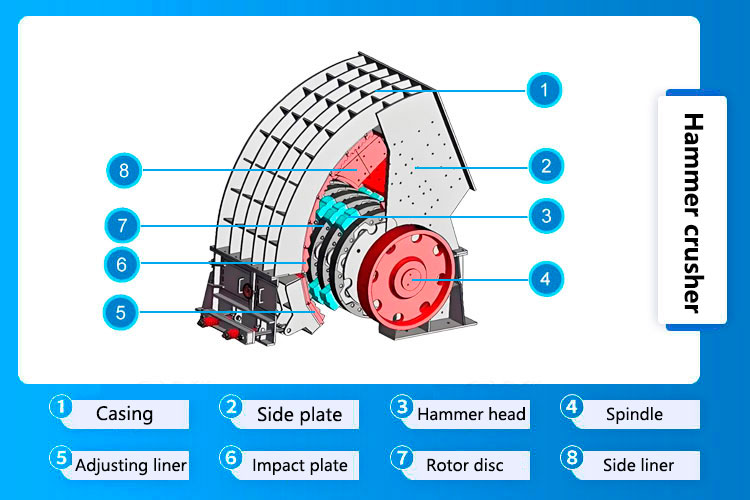

Composition structure

As a new type of crushing equipment, the hammer crusher has a unique and reasonable design structure, which not only improves production efficiency but also reduces production costs, and is widely praised by mine owners.

The hammer crusher is mainly composed of a casing, a motor, a main shaft, a rotor disc, a heavy hammer head, an adjustment lining, a crushing chamber, an impact plate and other parts.

The rotor and the heavy hammer head are important components. The rotor drives the heavy hammer to quickly crush the crushed materials. The heavy hammer heads of different specifications can also be replaced according to different needs to achieve efficient production.

Working principle

The hammer crusher is a motor driven rotor that rotates at high speed. The material is sent into the crushing chamber and is crushed by the impact of the hammer head. At the same time, the crushing chamber is also equipped with an impact plate. After the material is impacted by the hammer, it will rebound onto the impact plate and be crushed again by impact and friction. After crushing, the material that meets the particle size requirements is discharged through the screen plate, otherwise it will continue to be hit and ground by the hammer.

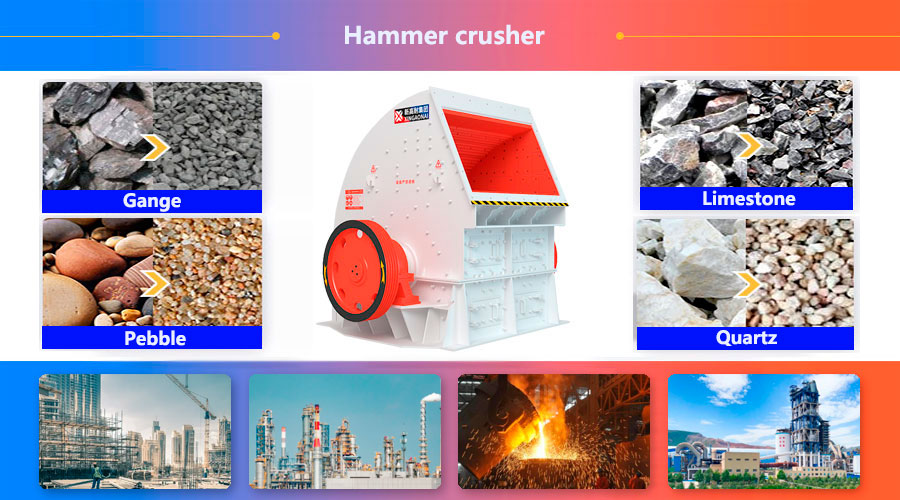

Application Field

Hammer crusher is widely used in construction, cement, chemical, metallurgy, coal and other industries with its reasonable design structure and efficient working principle, especially in crushing some brittle materials such as quartz stone and limestone. It not only has high crushing efficiency, but also can separate metals and other materials such as glass.

Advantages

Hammer crusher has a large feed inlet and can complete crushing in one go. One device takes into account the effects of crushing, fine crushing and sand making at the same time. There is only one step from the original stone to the finished product, and no secondary crushing and shaping are required, which can save about 40% of the operating cost. The whole process has only one core crusher, equipped with other auxiliary devices, with the characteristics of low investment and high operating efficiency.

Usage tips and daily maintenance

Adjust the feed port: Adjusting the feed port can effectively avoid the impact of materials when entering the machine and reduce the damage rate.

Regular maintenance: Regularly check and replace the heavy hammer head and other wearing parts in time to ensure the efficient operation of the machine.

Suitable materials: Selecting materials with appropriate hardness can improve the crushing efficiency and reduce the loss of the machine.

Adjust the hammer head: Different materials require different heavy hammer heads for crushing. Correctly adjusting the heavy hammer head can improve the output and crushing efficiency.

In summary, we have fully understood the structure, working principle, application field, advantages, usage tips and daily maintenance of the hammer crusher. How we choose crushing equipment needs to be determined according to the current factory environment and material requirements. Don't blindly think that the more expensive the better. Only by choosing the right crushing equipment can we achieve the minimum investment, high production efficiency and maximum benefits.(xingaonai)